Corrosion Fatigue Load Frames

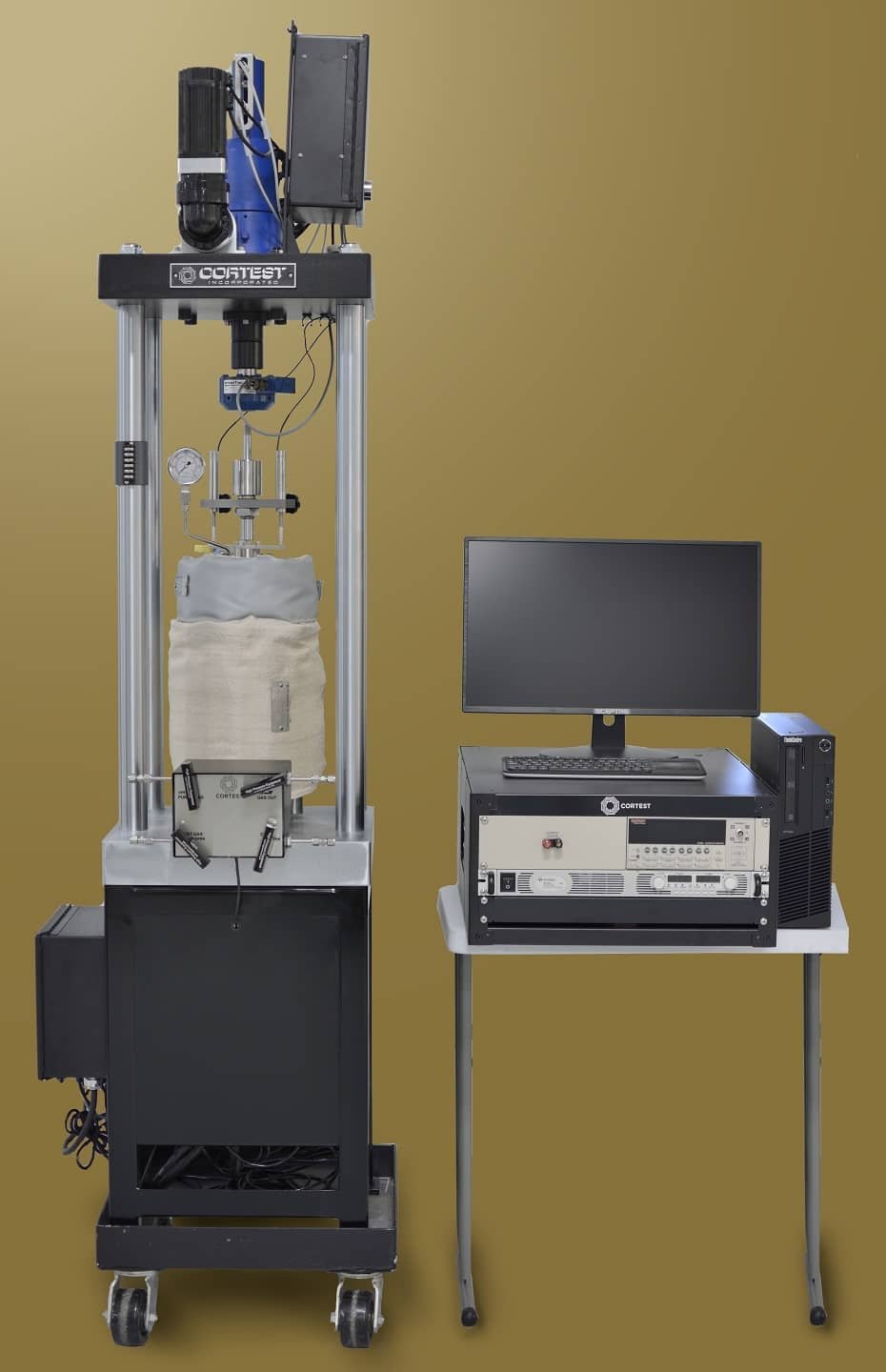

Cortest Corrosion Fatigue (CF) Load Frames are Testing Equipment that uses the widely accepted design of the SSRT/CERT Load Frames but with an advanced drive system and additional controls. The drive system utilizes a gear reduction system and a servo motor that is capable of performing cyclic testing at extension rates up to 3.5 mm/sec and fatigue frequencies up to 2 Hz along with all of the other capabilities of the SSRT/CERT Load Frames. This offers an economical alternative to those looking for a corrosion fatigue system at a fraction of the cost of servo-hydraulic test equipment. Each testing system has a built-in data acquisition system with an intuitive setup interface to easily prepare and monitor any test.

More Info

-

DRIVE MECHANISMS

SERVO MOTOR DRIVE WITH GEAR REDUCTION

ELECTROMECHANICAL LINEAR ACTUATORLOAD CAPACITIES OF

6,000 lbs, 10,000 lbs, 20,000 lbs

(2722kg, 4530kg, 9072kg)EXTENSION RATES UP TO

3.5 mm/s

FATIGUE FREQUENCY UP TO

2 Hz

-

-Materials of Construction:

Wetted Components (Pull Rods and Grips): Inconel 718, Hastelloy C-276, 316 Stainless Steel

Non-Wetted Components (External Load Components): 17-4 PH Stainless Steel;

-Load Capacities Available in 6,000 lbs (2722 kg) and 10,000 lbs (4,536 kg)

-Pressures Up to 62 MPa (8,992 PSI) with Autoclave Capacities Up to 3.4 Liters

-Temperatures Up to 600°C (1112°F)

-Electrically Isolated Grip Sets

-Fatigue Frequency: Up to 2 Hz

-Extension Rate Range: Up to 3.5 mm/s

-Load or Stroke Control

-Water-Cooled Feed-Thru Fittings Available

-Dual LVDTs for Maximum Sensitivity at Low Load Levels

-Environmental Chamber Options

-Custom Porting

HIP

NPT

Isolated Feed-Through

-

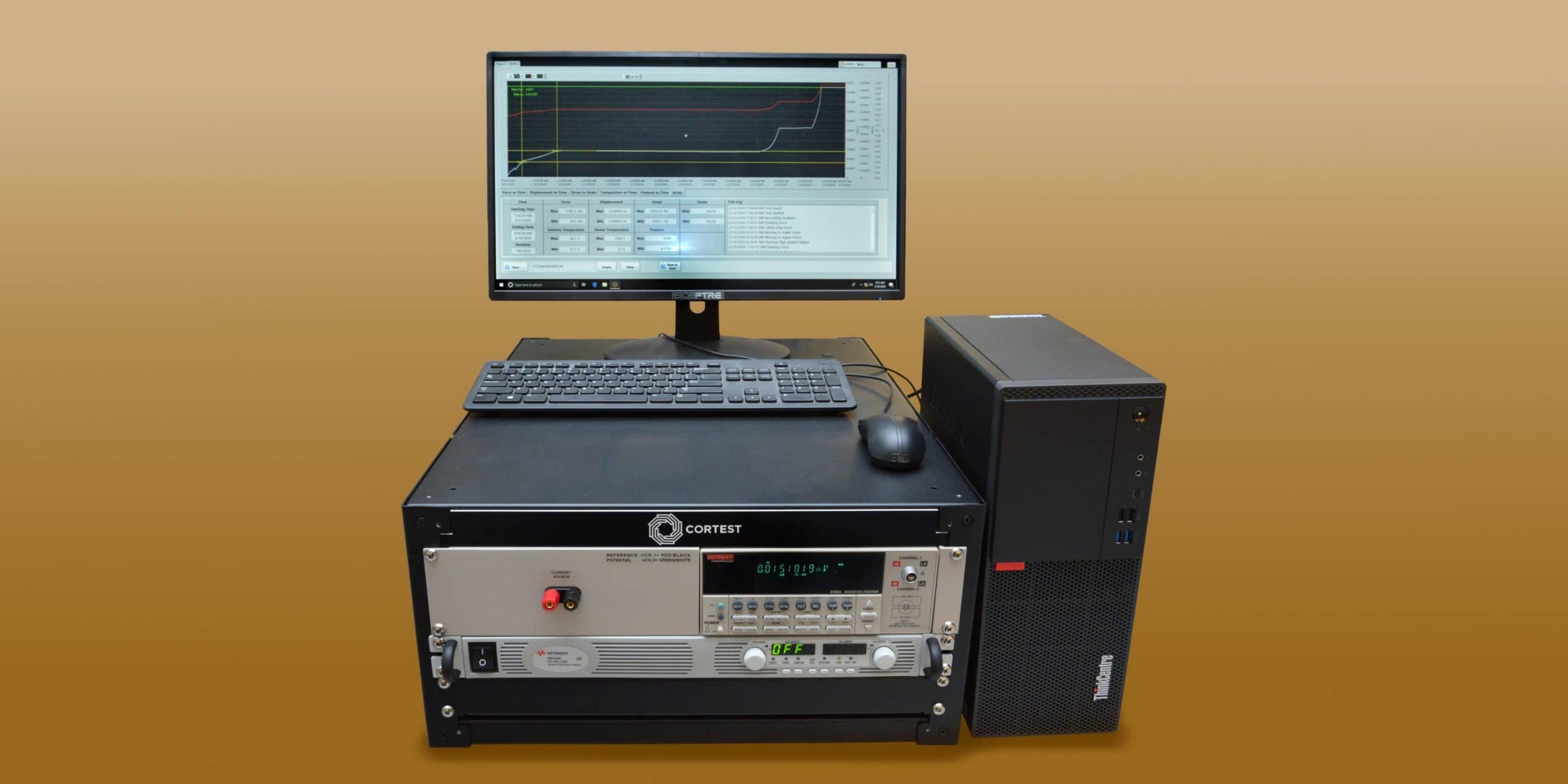

-PC Controlled Data Acquisition System

-Compact Tabletop Design

-Keyboard/Mouse Interface

-23” Monitor

-DCPD Capabilities (30A/20V Power Supply)

-LabVIEW Based Software Tests

Slow Strain Rate Test

Constant Load Test

Fatigue Test

Creep Test

-

-Slow Strain Rate Testing – NACE TM 0198

-Constant Load Testing – NACE TM 0177

-High Pressure, High Temperature (HPHT) Stress Corrosion Cracking (SCC)

-Electrochemical Studies

-DCPD Testing – ASTM E647

-New Product Development/Testing

-Supercritical Steam