About Cortest

Performance Under Pressure

Who We Are.

Since 1977, Cortest has been the industry leading provider of high quality corrosion and materials testing equipment by accepting and completing some of the most challenging projects in the field. Cortest has earned the reputation as the reliable go-to supplier of custom test systems. Throughout its history, Cortest has been involved in the testing industry, having previously provided corrosion testing services in its laboratories based in Houston, Texas, Columbus, Ohio, and Sheffield, England. The experience gained in our commercial laboratories significantly improved product design to assure safe and efficient operation meeting the specific needs of the researcher. Starting with the proof ring test system, Cortest’s product line has grown to include autoclaves, load frames, fume hoods, flow loops, deadweight testers, HIC tanks, magnetic drives, controls, software, and a wide range of specialty equipment. Many industry standard testing methods can be fulfilled using equipment specifically designed by Cortest to meet the requirements of its test standard.

Using our standard products as a baseline, customers can work directly with Cortest engineers to cost effectively design a fully customized apparatus to precise specifications. In addition to individual systems, Cortest frequently supplies fully outfitted new laboratories including test equipment, fume hoods, safety systems, data acquisitioning, glassware, and other supplies. Cortest equipment is available with PED, CSA, CE, DOSH, and the China Special Equipment Manufacture License certificates (upon request). To assure successful operation of Cortest equipment, installation, training, and commissioning services are available worldwide. Continued growth has resulted in Cortest having been awarded Fast Track 50 awards on nine occasions (awarded to the fastest growing firms in our region) and in 2014, Cortest again doubled its manufacturing facility.

Leadership Team

-

Dr. Allen F. Denzine

PRESIDENT

corrosion@cortest.com

440.942.1235 -

James Herrmann

SALES MANAGER

jherrmann@cortest.com

440.942.1235 ext. 102 -

Larry Gregerson

OPERATIONS MANAGER

lgregerson@cortest.com

440.942.1235 ext. 104 -

Genti Cini

ENGINEERING MANAGER

gcini@cortest.com

440.942.1235 ext. 105 -

Mark Unger

MANAGER, AUTOMATION & CONTROLS

munger@cortest.com

440.942.1235 ext. 103

Cortest Timeline

1977

Cortest Inc is founded by Dr. Allen. F. Denizen in Willoughby Ohio to manufacture corrosion testing equipment.

1980

Cortest ships its first high temperature / high pressure autoclave system.

1982

Cortest builds its first slow strain rate (CERT) system.

1983

Cortest International, Inc is formed to market corrosion testing equipment and services worldwide.

1984

Cortest Laboratories, Inc. (CLI) is formed in Houston, Texas to provide corrosion testing services (CLI sold to Honeywell in 2000).

1984

Cortest Columbus Technologies, Inc is formed in Columbus, Ohio with Dr. Neil Thompson, President.

1985

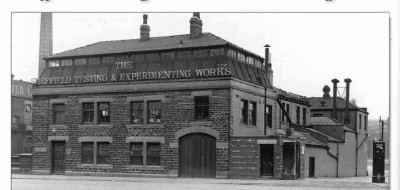

Cortest Laboratories LTD formed in Sheffield England with Dr. John Oldfield, to provide corrosion testing services.

1987

Cortest acquires Astro Design to enhance in design capabilities.

1991

Cortest acquires Petrolite Instruments (Houston, Texas) to manufacture corrosion probes, access systems and related instrumentation.

1993

Cortest Instruments opens sales offices in Abu Dhabi, Singapore, and London. Cortest quality system certified to ISO 9002.

1994

Cortest Instruments introduces a new line of E/R and LPR instrumentation. Cortest wins its first fast track 50 award.

1995

Cortest wins its second Fast Track 50 Award. Cortest Quality Systems certified to ISO 9001.

1996

Cortest develops pressure-balanced pull-rod technology.

1997

Cortest develops high temperature / high pressure flow loop technology. Corrosion probe and access fitting business.

1998

Cortest Laboratories LTD acquires Sheffield Testing Laboratories to enhance its testing and calibration services.

1999

Cortest wins Ohio Governor’s “E” Award for excellence in exporting.

2000

Cortest introduces low frequency corrosion fatigue systems

2004

Cortest controls updated to touch screen technology

2005

Cortest line of custom fume hoods is introduced.

2006

Cortest introduces high pressure / high temperature jet impingement system.

2010

Cortest wins its third Fast Track 50 Award.

2011

Cortest wins its fourth Fast Track 50 Award. Cortest developed supercritical steam flow loop product line.

2012

Cortest wins its fifth Fast Track 50 Award and is elected to Fast Track 50 Hall of Fame.

2013

Cortest wins its sixth Fast Track 50 Award. Cortest relocates to a new, larger manufacturing facility.

2014

Cortest Introduces H2S Scavenger System. Cortest wins seventh Fast Track 50 Award.

2015

Cortest introduces the world’s most precise DCPD testing equipment.

2016

Cortest introduces its line of high pressure and high temperature magnetic stirrers. Cortest wins ninth Fast Track 50 Award.

2020

Cortest introduces its hydrogen test enclosures.

2024

Cortest introduces its inclinable multiphase high pressure high temperature flow loop.